Ecoline

ECOLINES combines technology with affordability

ECOLINES combines technology with affordability

ROTOCON launches the ECOLINE series to meet your technology investment needs, striking a careful balance between the highest possible specifications and competitive prices.

Each ECOLINE label sorting and printing system has a compact footprint, easy-to-use control panel, and open machine design to maximize operator friendliness. The modem used for remote fault diagnosis and maintenance enables ROTOCON to quickly respond to software and driver related queries from operators.

Each ECOLINE label sorting and printing system has a compact footprint, easy-to-use control panel, and open machine design to maximize operator friendliness. The modem used for remote fault diagnosis and maintenance enables ROTOCON to quickly respond to software and driver related queries from operators. The ECOLINE series is manufactured according to ROTOCON's strict quality standards - sturdy, vibration free structures and the latest technology - as well as cost-effectiveness requirements.

We have commissioned these customizable models in Mauritius, Europe, Australia, and the United States outside of South Africa.

RSI 340 index | 440 slitting, inspection, and rewinding system

Easy to operate, providing a complete set of cost-effective standard functions for detecting and cutting printed labels.

Maximum speed: 300m/min

Unwinding diameter: 710 mm

Roll diameter: 450 mm

Unwinding: automatic end stop function and splicing station

Cutting accuracy: ± 0.2mm

Basic packaging for slitting: 6 razor blades

Ultrasonic roll diameter tracking

Counting: cumulative counting, linear counting, and single label counting

RDS 340 Die Cutting and Testing System

This dual-use platform has precision die-cutting and advanced drum and label detection functions. The two functions are easy to interchange and facilitate the production of blank labels. The semi-automatic turret rewinder allows your operator to prepare the next roll while the current roll is still running, thereby helping to speed up production time.

Unwinding diameter: 710mm

Roll diameter: 300mm

Maximum die-cutting width: 330mm

Maximum mechanical speed for full rotation: 200m/min

Available options: Strobe and Detection

Coming soon

Proposal 340 | 440 | 660 Flexographic Printing Machine

This cost-effective flexographic printing machine strikes a balance between register accuracy and high operating speed. RFP uses the latest Yaskawa servo drives and control systems. Each printing unit is driven by a separate servo motor - there are a total of 14 servo motors on one eight color printing machine and two die-cutting stations.

Maximum roll width: 340mm, 440mm, 670mm

Unwinding diameter: 1500mm

Roll diameter: 900mm

Repeat printing range: 254-609.6mm

Maximum mechanical speed: 150m/min

Available options: Roll paper rotating rod and cold foil (movable on the guide rail system)

ECOLINE PRO CLEAN Mesh Roller Cleaner

This ultrasonic mesh roller cleaning machine can efficiently and quickly remove all types of ink and dirt from any row of mesh roller pools. It is equipped with a drum rotating wheel and a constant temperature heating system, which can reduce any "hot spots" in the liquid that may generate high-intensity power levels and damage components.

Ultrasonic cleaning converts electrical energy into kinetic energy without generating dust and sewage, making it a more environmentally friendly method that requires cleaning solution to easily remove dirt from micropores.

Mesh roller length: 100-450mm

Number of vibrators: 16

控温范围:30-100°C

Ultrasonic power supply: 20A/220V

Electric heater power: 2.6KW

Facial cleanser working frequency: 40kHz

Rinse tank length: 450mm

Washing tank width: 450mm

RSH 340 slitting, detection, and rewinding system

Horizontal layout inspection slitting and rewinding machine, used for multifunctional label roll processing and handling, including booklets. It provides shorter setup time, compact design, and efficient operation.

Ultrasonic coil guide

Rail cutting accuracy: ± 0.2mm

Ultrasonic roll diameter tracking

Rolling backwards

Tension control during unwinding

Tension control of time, frequency converter control of wire drawing station

Unwinding and splicing table

Automatic linear counting

Single tag count

RDF 340 (English) | 440 Digital Printing Label Conversion and Organizing System

Offline more efficient extension of label decoration, such as flexographic printing, embossing, flat screen printing, and hot stamping.

Maximum roll width: 340mm

Maximum unwinding diameter: 700mm

Maximum winding diameter: 600mm

Maximum winding diameter: 600mm

Maximum die-cutting width: 330mm

Maximum mechanical speed for full rotation: 120m/min

Half turn maximum speed: 50m/min

Half turn repeat length: 100-457mm

Die cutting accuracy: ± 0.15mm

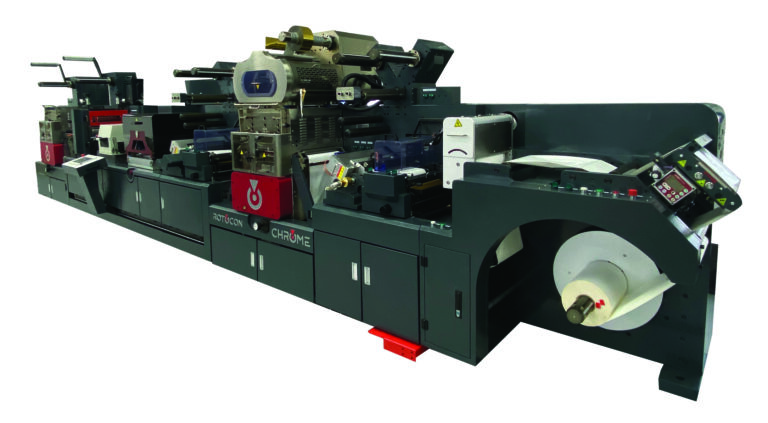

RFP Chrome 340 | 440 | 660 Flexographic Printing Machine

Our CHROME printing and post-processing equipment series provides customers with greater customizability and modular upgrade options without the need to spend a significant amount of money.

Each printing unit of the ECOLINE CHROME printing machine is equipped with Germany's latest Baum ü ller servo system, driven by two independent servo motors, one for the printing sleeve and one for the impression roller.

Maximum roll width: 350mm, 430mm, 530mm, 670mm

Unwinding diameter: 1500mm

Roll diameter: 900mm

Repeat printing range: 254-609.6mm

Maximum mechanical speed: 200m/min

Optional: Hot air or infrared drying system for water-based ink, cold foil - movable on track

ECOLINE PRO Installation Tablet Mounter

An entry-level machine designed to meet three requirements: cost-effectiveness, ease of operation, and providing the highest precision and highly repeatable accuracy for operators manually installing printing plates. The 650 line camera achieves a 70x magnification ratio through a 482.6mm high-resolution display screen, presenting clear and bright images, greatly improving the accuracy of plate mounting.

Maximum barrel length: 600mm

Maximum barrel diameter: 800mm

Voltage: 220V (single-phase, 50-60Hz)

CONTACT INFO

We'd love to chat with you. Please contact us using the details below.

CONTACT US

- +27 (0) 21 975 6763/65

- info@rotocon.world

- 19 Mills Street, Durban, Cape Town

TRADING HOURS

- Monday: 8am – 6pm

- Tuesday: 8am – 6pm

- Wednesday: 8am – 6pm

- Thursday: 8am – 6pm

- Friday: 8am – 6pm